- Cnc simulator software#

- Cnc simulator code#

- Cnc simulator professional#

- Cnc simulator simulator#

- Cnc simulator free#

In this video, now the digital twin demonstration the MTAB smart factory setup consists of ASRS, AGV, FLEXMILL, FLEXTURN, Transfer conveyor, Gantry loading and unloading, Vision Inspection, Assembly station with Robot etc. For this, i have decided to subtract a moving cylinder from a box.

Cnc simulator simulator#

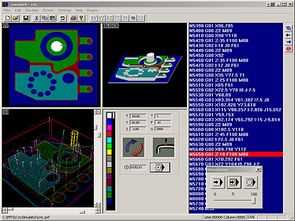

Capable of creating 2D and 3D CNC designs, Fusion 360 also has a g-code editor and CNC simulator based on your chosen toolpaths.

Cnc simulator software#

With a huge market share and a favorite of many makers, Fusion 360 is a great all-in-one CAD/CAM software for CNC.

Cnc simulator free#

The simulation should be 3D and the user should be able to rotate and zoom during the simulation. Free for students and free trial, then 495/year.

Cnc simulator code#

Function set is highly relevant for machine tool applications and contains everything instructors and students require for. A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard GM code (Fanuc System A). Designed with students in mind, it enables young people to gain first-hand experience of programming and operating cutting-edge CNC for milling and turning. I dont want to simulate the G-Codes, instead, I want to simulate by getting the x,y,z position of the milling tool. That’s why we’ve put together the FANUC CNC Simulator. This is a smart, high-performance solution that’s ideal for verifying, simulating, and optimizing turning, drilling, and milling for both 3 and 5 axis CNC machines.

Cnc simulator professional#

Hexagon NCSIMUL is a highly advanced CNC simulator designed for professional use. The main features of digital twin is useful in incorporating Multiphysics simulation, data analytics, and machine learning capabilities, digital twins are able to demonstrate the impact of design changes, usage scenarios, environmental conditions, and other endless variables – eliminating the need for physical prototypes, reducing development time and improving quality of the finalized product or process. Hi, Im going to develop a cnc simulator for my cnc machine. Hexagon NCSIMUL Best CNC simulator for complex 5 axis operations. With the help of powerful software, you achieve synchronization between product engineering, manufacturing engineering, production, and service operations to maximize your production efficiency. CNC Simulator Pro: Simulation: Best Free CNC Software Programs 2022 In Microcontroller-based CNC control systems (GRBL/Arduino, Raspberry Pi, TinyG), the process flow is as shown below.

.jpg)

The functionality of the simulator: preparation of texts of control programs of turning operations in the format of a standard GM code, checking control programs for syntax and technological errors, playing on the computer screen (or other computing device) three-dimensional graphic models of the main components of the lathe machine and metal-cutting tools to simulate the process of turning metal, the three-dimensional visualization of the process of forming parts during turning on the compiled control programs, visualization of toolpaths, implementation of interactive user interaction with the simulation model of technological equipment.Digital twin is a virtual-physical connection which helps you to analyze how a product will perform under various conditions and make adjustments in the virtual world to ensure that the next physical product will perform exactly as planned in the field. Material processing is performed on two axes in the horizontal plane.įield of application of the software product: educational process using computer technology: laboratory lessons of students in computer classes, distance learning, demonstration support of lecture material in the group of areas of training and specialties: «Metallurgy, Engineering and Material Processing». The basis of the three-dimensional simulation model is a lathe with a classical arrangement of units, equipped with a CNC system, an eight-position turret, a three-jaw chuck, a tailstock, a coolant supply system and other machinery. A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard GM code (Fanuc System A).

0 kommentar(er)

0 kommentar(er)